Infrared Scanning

Infrared scanning detects a rise in temperature, thus allowing it to be used in a variety of applications, including during normal operations.

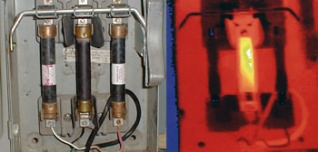

Infrared scanning is used to scan building envelopes, electrical components and connections for excess heat. When there is a presence of heat, this indicates resistance. In turn, cause of this resistance is most often related to failing components, poor connections, corrosion, load imbalance and/or harmonics.

Many benefits can be derived from infrared scanning including:

Infrared scanning is used to scan building envelopes, electrical components and connections for excess heat. When there is a presence of heat, this indicates resistance. In turn, cause of this resistance is most often related to failing components, poor connections, corrosion, load imbalance and/or harmonics.

Many benefits can be derived from infrared scanning including:

- locating potential problems prior to plant start up;

- reduced downtime and emergency repairs;

- reduced labour required for preventative maintenance by locating specific areas that require repairs;

- minimized scheduled maintenance times;

- extended equipment life;

- increased reliability of plant power distribution system;

- permits the evaluation and verification of repair work;

- prevention of accidents, personal injury and property damage.